Application & Benefits Of Precast Concrete

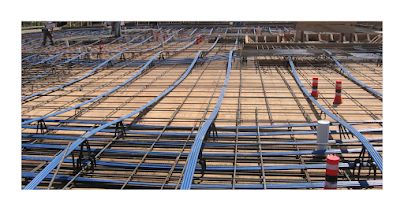

The precast concrete type is a type of concrete that has been prepared by casting and curing off-site, often in a controlled environment, employing reusable molds. Precast Concrete components may be joined to other elements to create the complete structure. It is usually used for structural elements like beams, wall panels and stairs, columns, floors pipes, tunnels, and many more.

Structural steel frames are an alternative to pre-fabricated components for structural use, but Precast Works can be more cost-effective and often more efficient. Most buildings nowadays incorporate the combination of both techniques for construction that may include structural steelwork, concrete in-situ as well as precast works elements.

Applications

Reinforced concrete is typically used in the construction of structural structures because of its durability, strength, and cost-effectiveness. The Precast in UAE can be used to perform the following functions:

To build columns, beams floor slabs, foundations, and other structural members to support buildings.

Precast works can be used for the production of walls or panels for cladding paneling to be used in constructions.

In order to make ready-cast ready-stress components to be used in structures.

To create parts to be used in infrastructure construction projects. parts like bridge spans as well metro line viaducts are typically cast in the casting yard.

To create precast works like precast tanks for water, septic tanks draining chambers, railroad sleepers flooring beams and boundary walls, and water pipes.

Because it can be molded to the shape of your choice, precast in UAE could be used to create unique designs like sculptures, boats, and the like.

Benefits in the Precast Design and Construction

Precasting is efficient in the production of large quantities of similar elements. For example, when building affordable housing with similar apartments could make use of precast concrete to create floor slabs and wall slabs for all apartments before lifting the slabs into position and joining the slabs.

When it's done in a specifically constructed Precasting Yard or factory It helps make the construction more efficient. This process of construction is carried out in the ground instead of at high elevations. It is possible to do it in an air-conditioned structure which eliminates the issues of the elements like rain, dust, or cold heat.

Specific forms (molds) can be made to make many copies on the identical part. The specialized equipment is employed to create the precast concrete, move it, and pour concrete. Concrete. Curing takes place in a safe setting. This implies it is possible that high-end quality in cast elements can be extremely high.

Because the components can be constructed prior to the construction, construction can be extremely quick. When using cast-in-situ construction engineers must construct each set of components once the previous set is completed however, this can take time since concrete usually requires 28 days before reaching its maximum strength

Comments

Post a Comment